What Is A Timing Belt?

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving

FEP film is the acronym for Fluorinated ethylene propylene. It is a copolymer of tetrafluoroethylen and hexafluoropropylene It differs from the (polytetrafluoroethylene) PTFE resins in that it is melt processable using screw extrusion techniques and conventional injection moulding. FEP film (Fluorinated ethylene propylene) was invented by Du-Pont and is sold under the brand name Teflon FEP. Teflon is a brand name owned by Du-Pont.

The composition of FEP is very similar to fluoropolymers PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy polymer resin). PFA film and FEP film both share PTFE’s unique properties of low friction and non-reactivity, but are far more easy to form. FEP it is highly transparent and resistant to sunlight and is also is softer than PTFE. PFA film melts at 260 °C.

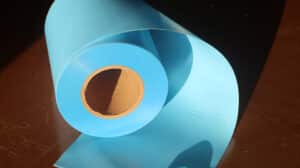

What form do you sell this on?

We stock this in a thin film that has a nominal thickness of 0.035 mm thick. Around 0.0015″. Our master batch rolls are 300 mm wide x 493 meters long. We can slit this product to your specific width and offer as slit rolls. If you prefer we can supply this on rolls that are 30 meters long. Here is an example of our pricing.

FEP film Price example

50mm x 30mtr – £10.82 per roll ex VAT

We can slit this ranging from 15mm wide up to 300mm wide depending on stock widths at the time.

What can we use this for?

This can be used to seal PTFE coated fabrics to the edges of PTFE fabric conveyor belts. The FEP film is used to bond the conveyor belt edge reinforcement to the belt itself.

What is the lead time for your FEP film?

This is ex stock. Like most of our slit products we aim to dispatch the same day if ordered before 1.00 pm. If not, it would leave the following day on UPS.

How can we purchase this from you?

You can contact our UK based Technical Sales office on +44 (0)1422 366386 or contact us via email at sales@techbelt.com

Timing belts are crucial components in conveyor belt systems and other machinery, ensuring precise synchronisation between the moving

Wow, what a journey it’s been! We’ve always believed in the power of LinkedIn to help us connect,

UHMW tape Ever struggled with things wearing out too quickly or noisy machinery that’s just a constant headache?