Who Invented Conveyor Belts?

Who invented conveyor belts? People often credit Thomas Robins with inventing the modern conveyor belt. In 1892, he

Step 1: Clean the Surface

Start by cleaning the surface where you plan to apply the tape. Use a clean cloth and an appropriate solvent to remove any contaminants like oil, grease, or dirt.

Step 2: Measure and Cut the Tape

Next, measure the length of the surface you want to cover and cut the tape to the desired length.

Step 3: Remove the Release Liner

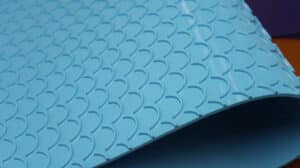

Then, remove the yellow corrugated release liner from the tape to expose the adhesive side.

Step 4: Apply the Tape

Carefully apply the tape to the surface. Ensure that you align it correctly and cover the entire area. Use gentle pressure to make sure the tape adheres properly.

Step 5: Smooth Out Air Bubbles and Wrinkles

Finally, use a roller or a smooth, flat tool to smooth out any air bubbles or wrinkles that may have formed.

By following these simple steps, you can achieve a professional-grade application of PTFE adhesive tape. Contact the team today to learn more about PTFE adhesive tape and how it can benefit your company. You can trust its non-stick properties and temperature-resistant coating to get the job done right.

Follow our step by step video guide Here

Who invented conveyor belts? People often credit Thomas Robins with inventing the modern conveyor belt. In 1892, he

Conveyor belts are used in a wide variety of industries and applications to efficiently transport materials. Here are

Wondering how to design a conveyor belt that perfectly suits your specific needs? At Techbelt USA, we make